Quality Assurance at Meskay & Femtee

QUALITY ASSURANCE

Ensuring Excellence Always

At Meskay & Femtee Trading Company (Pvt.) Ltd we assure the quality of rice in all phases of the production process thereby making sure our customers get the best quality product every time.

Standards of Quality

TOP CLASS QUALITY CONTROL LABORATORY

Meskay & Femtee Trading Company (Pvt.) Ltd. boasts a profound understanding and expertise in adhering to both national and international rice quality standards. This encompasses compliance with Pakistan PS-3342 (ICS.No.67.060) Revision 2007 standards for rice processing, IRRI guidelines, and CODEX regulations.

Our state-of-the-art Quality Control Laboratory stands as a unique and distinguished facility, equipped to ensure the highest standards of quality. We proudly hold certifications for Total Quality Management systems, including ISO 9001:2008 (maintained since 2010), HACCP, GMP, USFDA, ISO 9001:2015, Kosher, and Halaal. These certifications underscore our commitment to quality assurance.

Quality-related reporting undergoes meticulous scrutiny by our QC Manager, Mill Manager, Production Manager, and Senior Management. At Meskay & Femtee, we spare no effort in delivering products that meet and exceed defined specifications, ensuring customer satisfaction.

ADVANCED QUALITY CONTROL LABORATORY

Setting the Bar High

Meskay & Femtee Trading Company (Pvt.) Ltd. maintains an annual contract with a government-authorized laboratory, guaranteeing the absolute precision of all our equipment. This unwavering commitment ensures that our rice analysis and testing consistently meet the highest quality standards, an achievement duly recognized by the Government Authorized laboratory. Additionally, we employ a cutting-edge one-pass mill, equipped with a state-of-the-art Canonscan 5600f Grain Scanner. This advanced technology streamlines the process of converting paddy into rice while ensuring thorough inspection and grading of grains, further reinforcing our dedication to quality.

QUALITY ASSURANCE PROCESS

Ensuring Robust Quality Control

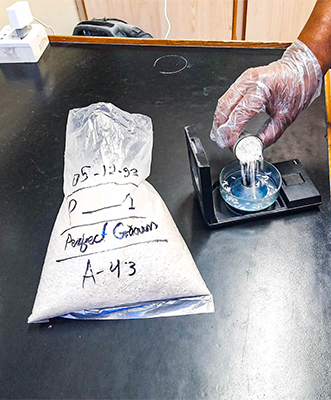

At Meskay & Femtee, our commitment to these leadership principles is unwavering, reflecting our dedication to delivering excellence in every aspect of our business operations. At Meskay & Femtee Trading Company we take quality seriously. Our rigorous quality assurance procedures are meticulously followed to guarantee the highest standards from the moment we select rice to its final processing in our mills. Our state-of-the-art laboratory is equipped with cutting-edge technology to monitor various aspects of our products:

- Physical Characteristics: We employ top-of-the-line equipment such as Top Loading Balances, Digital Weighing Scales, Moisture Meters, Rice Graders, Rice Huskers, Rice Polishers, Milling Meters, and Inspection Trays to assess physical attributes.

- Cooking Test: We conduct thorough cooking tests, evaluating factors like Elongation Ratio, Cooking Time, Water Uptake, and Volume Expansion to ensure optimal performance in the kitchen.

- Sensory Analysis: Our team evaluates sensory aspects, including Whiteness, Gloss, Smoothness, and Tastiness, to guarantee a delightful culinary experience.

- Purity Tests: We rigorously assess product purity to maintain the integrity of our offerings.

In addition to our in-house quality assessments, we collaborate with external certified laboratories for comprehensive chemical analysis whenever necessary.

We pride ourselves in being present at all stages of rice from farming to the time it reaches your plate and that is the guarantee to Meskay & Femtees Seal of Quality.

LEADERSHIP PRINCIPLES

The Foundation of Quality and Ethical Work

At Meskay & Femtee Trading Company we uphold a set of leadership principles that form the cornerstone of our commitment to quality and ethical practices. These guiding directives are rigorously followed in all aspects of our operations, ensuring that our work consistently meets the highest standards. Any deviations from these principles are promptly identified and addressed:

- Stringent Raw Material Evaluation: Every incoming batch of raw materials undergoes thorough scrutiny, and any sub-standard materials are promptly rejected.

- Optimal Yields: We strive for excellence in our processes, aiming for high yields at all times.

- Zero Broken Grains in Bran (Powder): We maintain a strict standard of quality, ensuring that there are no broken grains in our bran products.

- No Head Rice in Broken Grains: Our commitment to quality extends to our rice products, where head rice is never mixed with broken grains.

- Negligible Paddy and Good Grains in CSR: In our final product, the presence of paddy and good grains is kept to an absolute minimum, upholding our quality standards.

- No Shortweighted Bags: We guarantee that none of our bags are underweight, providing our customers with full value.

- Accurate Shipment Loading: Our shipments are meticulously loaded to avoid any discrepancies in quantity.

- Eliminating Excess Stock: We take care to ensure that no excess stock is included in our consignments, maintaining precision in our deliveries.

- Container Security: Prior to loading, all containers are thoroughly inspected and sealed to prevent theft or tampering.

- Photographic Documentation: For added security, we document every container loading with photographs, archiving this information for reference.

At Meskay & Femtee, our commitment to these leadership principles is unwavering, reflecting our dedication to delivering excellence in every aspect of our business operations.

WATER PROCESSING

Innovative Water Treatment Solutions

Meskay & Femtee Trading Company (Pvt.) Ltd. is at the forefront of revolutionizing water treatment in the rice processing industry. We've taken proactive steps to enhance the quality of our process water, ensuring it meets the highest standards. Our installation of RO Plants in the PQ/Eastern Zone sets us apart as a leader in this regard.

The RO Plants at a Glance:

- A-43 Plant: With an impressive capacity of 15,000 gallons per day (GPD), this facility is dedicated to providing clean, potable water to our polishers. We deliver a remarkable 40 liters of purified water per hour to each polisher, guaranteeing optimal working conditions.

- A-44 Plant: Boasting a capacity of 10,000 GPD, this plant doesn’t just serve our processing needs but also provides drinking water for our dedicated staff. We prioritize the well-being of our team members, ensuring they have access to safe and clean drinking water throughout their workday.

At Meskay & Femtee, we understand that water quality is a crucial aspect of our operations. Our commitment to innovation and excellence extends to every facet of our business, including water processing.

Interested in discovering how we can be the ideal supply chain partner for you?